In the rapidly evolving landscape of data center construction, materials play a pivotal role in...

Explaining the Concept and Relevance of FRP in Data Center Construction

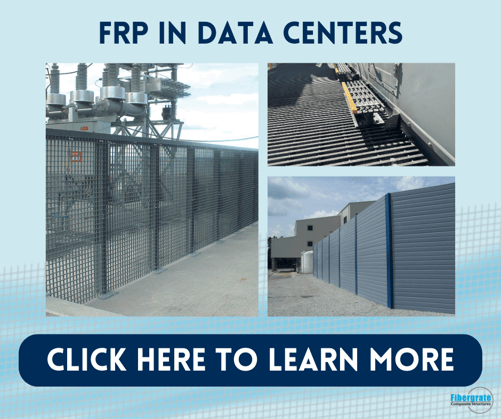

In the rapidly evolving landscape of data center construction, materials play a pivotal role in ensuring reliability, durability, and safety. One such material that has emerged as a game-changer is fiberglass-reinforced plastic (FRP). This innovative composite material is a blend of reinforced fiberglass and plastic resins, resulting in a lightweight yet incredibly strong product.

The potential impact of utilizing FRP materials in the construction of data centers cannot be overstated. The critical role FRP products will play in shaping modern data centers is not only due to the durability and corrosion resistance of the materials, but also the increased safety and efficiency these products provide. In this blog piece, we will explore the core characteristics that make FRP the material of choice for flooring, structural components, and various other applications within data centers.

Benefits of FRP in Data Centers

FRP offers a plethora of benefits in various industries, including data center construction. Its lightweight nature, coupled with remarkable strength, minimizes installation and maintenance costs while ensuring structural integrity. FRP is highly resistant to corrosive chemicals, making it an ideal choice for environments prone to moisture and chemical exposure. Its non-conductive properties enhance electrical safety, an essential consideration in data centers. Whether used for flooring, structural components, or other applications, FRP stands out as a versatile and cost-effective material that fosters durability, safety, and sustainability in modern construction projects.

FRP Flooring Solutions for Data Center

FRP products can be manufactured to have a slip-resistant surface. This anti-slip surface ensures safety in environments where foot traffic and cable management are paramount. FRP is corrosion-resistant, which is crucial for withstanding the wear and tear of rooftop applications. The open grid design of FRP flooring for data centers permits efficient airflow, enhancing the cooling systems. Furthermore, its lightweight properties simplify installation and maintenance, reducing costs.

Structural Applications of FRP in Data Center

FRP's exceptional strength-to-weight ratio makes it an ideal choice for constructing server enclosures, equipment racks, and cable trays, providing robust support for critical hardware. The non-conductive nature of FRP enhances electrical safety and will not interfere with the performance of your products. The corrosion-resistant properties are essential in environments prone to moisture and humidity, safeguarding the longevity of structural components of data centers.Fire Safety and FRP in Data Centers

FRP materials are inherently fire-resistant and do not contribute to the spread of flames. In the event of a fire, FRP components emit very low levels of smoke and toxic fumes, improving the chances of safe evacuation and minimizing potential damage to equipment.

FRP in Data Centers and Energy Efficiency

The thermal properties of FRP provide effective insulation, reducing the energy required for cooling systems. Additionally, FRP's lightweight composition results in decreased structural load, contributing to overall energy savings. By using FRP for various applications, data centers can improve energy efficiency, lower operational costs, and reduce their carbon footprint.

Challenges and Considerations

FRP offers numerous advantages in data center construction; however, it is also essential to acknowledge potential challenges and considerations. Firstly, proper installation and maintenance are critical, as any damage or wear to FRP components can compromise their effectiveness. Careful planning is required to ensure that FRP solutions meet specific load-bearing and fire safety requirements. Additionally, budget considerations and the initial cost of FRP materials should be weighed against the long-term benefits. By addressing these challenges and considerations, structural engineers can make informed decisions to maximize the benefits of FRP while mitigating potential issues.

How Product Solutions by Fibergrate Help in Building the Data Centers of Tomorrow?

Fibergrate FRP is at the forefront of shaping the data centers of the future. Our innovative products are revolutionizing data center infrastructure with a strong focus on durability, safety, and sustainability. From anti-slip flooring to structural components, Fibergrate's FRP solutions offer exceptional strength-to-weight ratios, corrosion resistance, and thermal and electrical non-conductivity, critical for data center environments. Here are a few Fibergrate product solutions that we can offer to contribute to the creation of more efficient and eco-conscious data centers, setting a new standard for the industry's future.

1. Non-Conductive FRP Access Platforms & Stairs

Fibergrate offers a range of anti-slip and corrosion-resistant stair and platform solutions tailored to address specific safety requirements within the data center environment. Our extensive lineup of stair and non-conductive access platform solutions is engineered to surpass OSHA standards, ensuring data center personnel experience optimal safety, structural integrity, and durability.

2. Substation Oil Containment FRP Grating

Fibergrate’s corrosion-resistant oil containment gratings effectively prevent oil seepage, safeguarding critical data center equipment and ensuring operational continuity. Their lightweight design simplifies installation and maintenance.

3. Sound-absorbing Wall Planks

FRP sound-absorbing wall barriers/planks effectively reduce sound reverberation, enhancing acoustic comfort and maintaining a conducive work environment. Lightweight and durable, they are easy to install and maintain, making them an ideal choice for server rooms and data centers.

4. Traffic-Rated Utility Trench Covers

FRP traffic-rated utility trench covers offer a robust solution for securely concealing utility channels and trenches in high-traffic areas. These FRP covers are lightweight and easy to handle, making installation and future maintenance significantly easier and safer. Utility trench covers made of FRP are also exceptionally durable and capable of withstanding heavy loads. They are non-conductive and resistant to corrosive chemicals as well.

5. Electrically Non-Conductive (ENC) Fencing, Screening, and Barriers

FRP Electrically Non-Conductive (ENC) fencing, screening, and barriers offer superior protection around electrical equipment and high-voltage areas. These products serve as a critical safety measure in data centers, contributing to the overall protection of personnel and equipment.

Future Trends: FRP in Data Centers

As data centers continue to evolve, FRP is expected to play a pivotal role in achieving higher levels of efficiency, durability, and sustainability. Innovations in FRP applications will likely focus on creating modular, customizable solutions that can adapt to the dynamic needs of data centers. Enhanced fire-resistant FRP materials and advanced thermal properties will contribute to increased safety and energy efficiency. Moreover, the incorporation of smart technology within FRP components is expected to facilitate real-time monitoring and management, optimizing data center performance and reinforcing FRP's position as a cornerstone of future data center design and construction.